Atlas Nail Base Fasteners are required for proper mechanical attachment of all Atlas ACFoam® Nailable Insulation Systems.

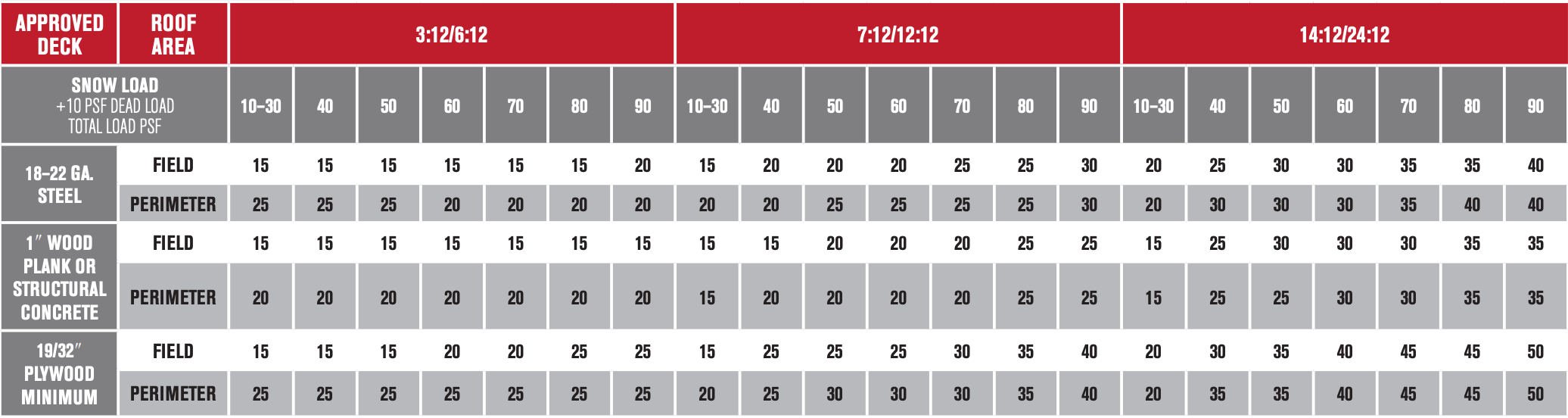

ATLAS NAILABLE INSULATION FIELD AND PERIMETER FASTENING PATTERNS

- Tested by an independent 3rd party testing laboratory

- Verified by a 3rd party engineering firm

- Meet the FM 1-60, 1-75, 1-90 and 1-105 Windstorm Classifications

- Accomodate FM 1-29 prescriptive enhancement options for corners with one fastener per sq ft (min. 32 fasteners per 4ʹ × 8ʹ board)

- Meet ASCE 7-10 requirements (available upon request)

ROOF PERIMETER AREA DEFINITION

A band equal in width to 10% of the lesser roof plan dimension or 40% of the mean roof height, whichever is less (minimum band width is 4.0ʹ).

Note: Perimeter area includes corners and overhangs.

ATLAS ACFOAM® NAILABLE ROOF INSULATION FASTENING REQUIREMENTS

ROOF PITCH TABLE 1

- Table 1 applies to roofs in areas of wind velocity not exceeding 110mph, Exposure C, Importance Factor I = 1.15, and a maximum mean roof height of 60ft.

- Table 1 is valid only for use with Atlas ACFoam® Nailable Roof Insulation and Atlas Nail Base Fasteners.

- Refer to Atlas ACFoam® & Nailable Roof Insulation Fastening Pattern Guide or Atlas Nailable Insulation Guide for appropriate fastening patterns.

- When plywood is used as the top surface of the ACFoam® nailable insulation, additional fastening is required. See Atlas Technical Bulletin: TB-1.

- Perimeter area includes corners and overhangs.

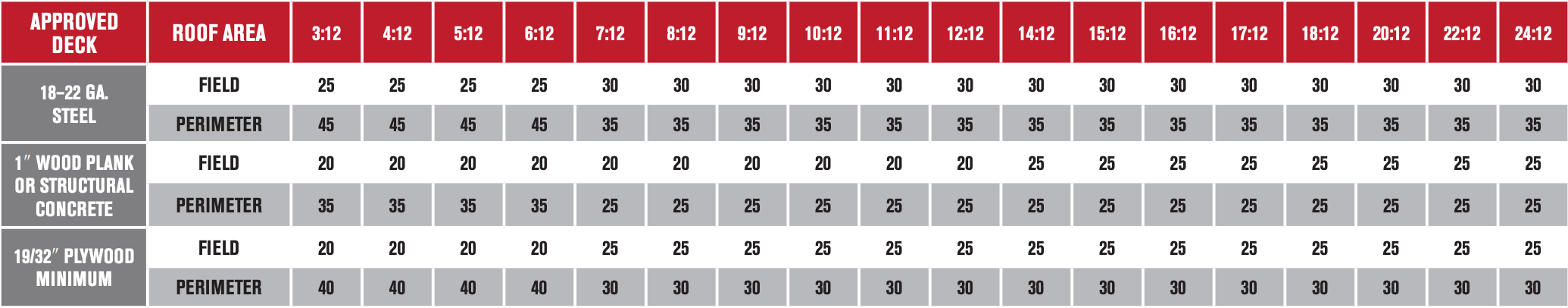

ROOF PITCH TABLE 2

- Table 2 applies to roofs with no snow load and a wind velocity over 110mph, but not exceeding 146mph, in combination with 10psf Dead Load, Exposure C, Importance Factor I = 1.15, and a maximum mean roof height of 60ft.

- Table 1 is valid only for use with Atlas ACFoam® Nailable Roof Insulation and Atlas Nail Base Fasteners.

- Refer to Atlas ACFoam® & Nailable Roof Insulation Fastening Pattern Guide or Atlas Nailable Insulation Guide for appropriate fastening patterns.

- When plywood is used as the top surface of the ACFoam® nailable insulation, additional fastening is required. See Atlas Technical Bulletin: TB-1

- Perimeter area includes corners and overhangs

APPROVED DECKS

- 18–22 ga. Steel Deck (3/4ʺ through deck [top flange])

- Structural Concrete (2500 psi min.) 3/16ʺ pre-drilled pilot hole required (1ʺ penetration into deck)

- 1ʺ minimum Wood Plank and T&G (1ʺ penetration into deck)

- 19/32ʺ minimum Plywood (1/2ʺ through deck)

- FM 1-60, 1-90, 1-105:15 Fasteners (min.) for ACFoam® CrossVent® and ACFoam® Nail Base insulation (Steel Deck and Structural Concrete)

- For projects requiring FM wind rating, FM approved assembly, including deck and covering, is required

ATLAS NAIL BASE FASTENER INSTALLATION RECOMMENDATIONS

- The fasteners should be installed using an 1800–2500 RPM (max.) screw gun with a hardened drive bit. Standard electric drill guns are not recommended for installation of Atlas Nail Base Fasteners.

- Steel decks are acceptable deck types provided they are between 18 ga. (max) and 22 ga. (min). Be sure to determine the gauge of the deck. For 16 ga. or heavier, consult the Atlas Technical Department